Let us return to the Useless Machine topic one more time.

Classical useless machine usually made out of four electrical components, namely:

- Electrical battery.

- Gear motor.

- DPDT switch (usually toggle, sometimes rocker).

- Micro-switch.

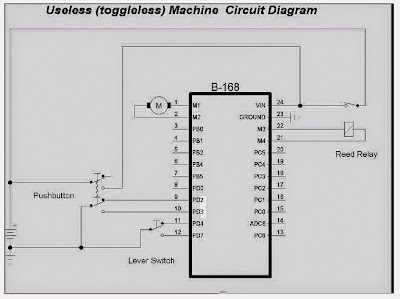

This is probably minimal set: it is hard to imagine anything more efficient. But once an idea came to my mind: maybe such a machine is not absolutely perfect. Useless machine must cut itself out of power as soon as it returns to the original state. That achieved with help of the micro-switch. Machine arm,while returning back, pushes switch, its normally closed contact becomes open, machine fully stops and looks dead. But if tester tries to move an arm manually, micro-switch is released again, its closing contact provides power to the motor. That case is visible on the clip of Rocker Switch Useless Machine starting at second 19. So machine here actually is not dead, it just plays dead! That's good opportunity for the new design : make the machine, which will allow manual rotation of the arm, when machine is turned off. In other words make the machine really dead at the end of its working cycle. To achieve that I decided to get rid of micro-switch and use for backward movement an energy stored in the capacitor, charged while machine arm moves forward, . Below you can see circuit diagram of such a machine:

When switch connects motor to the battery and motor moves the arm forward, electrical current is flowing through the circuit of diode and relay, mounted in parallel to the motor. Relay is forced to close its normally opened contact. Through that contact (and small resistor) capacitor is connected to battery and receives some charge.

When arm turns the switch back, motor is disconnected from battery, but connected to the capacitor in the opposite polarity. Motor rotates backward and returns arm to its original state. Diode now stays in the opposite direction on the way of electrical current, so relay contact stays open and capacitor is disconnected from the battery. Capacitor mostly is discharged providing the movement of the motor, the rest will be discharged through the stopped motor winding. You see, in theory it looks simple. But I must tell you that this design is much more demanding on the spec of components, compare to classical schematic. After some trial and error iteration I came up to the next set component:

- Solarobotics gear-motor GM17 ( I could not make it working reliably with GM2 or other motors with similar spec).

- Super capacitor 0.1 F. (I used NEC 5.5 V capacitor). Bigger capacitor would be fine but smaller probably not.

- 5V relay. Here type is not that important.

- Schottky diode. Here type is not that important.

- Resistor 5 Ohm. It is optional but it keeps electrical current trough the battery under 1 Amp at the beginning, when the capacitor is fully discharged. Type does not matter here, but better to have 0.5 W.

- Four 1.2 V rechargeable batteries. Type does not matter.

I published more detailed description on instrcuctables site

Update 11/12/2017. fixed bug in diagrams: missing wire between switch terminals.